- Model NO.:zf014

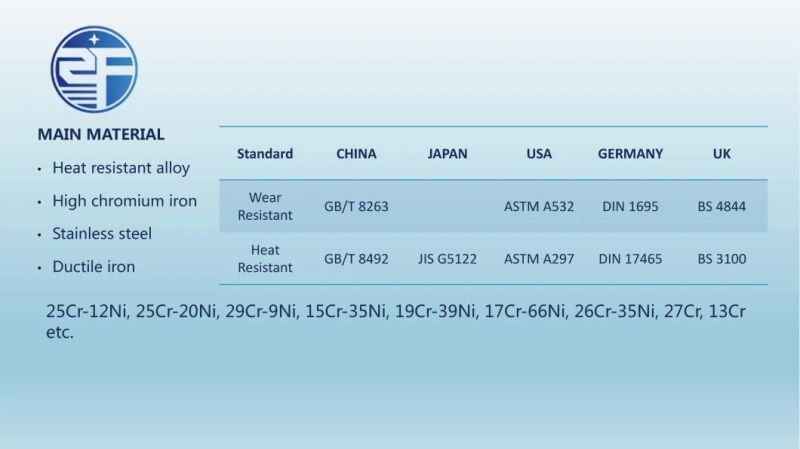

- Material:High Chromium Alloy

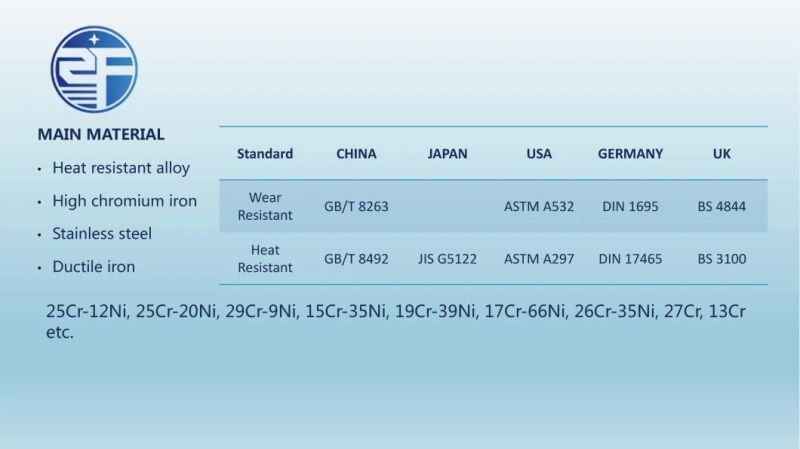

- Material Standard 1:ASTM A532

- Raw Material:Chromium

- Material Standard 2:DIN 1695

- Material Standard 3:BS 4844

- Material Standard 4:GB,T 8263

- Transport Package:Wood Case

- Specification:800mm*800mm*800mm

- Trademark:zf

- Origin:China

- HS Code:8474900000

- Production Capacity:1000 Tons Per Year

Basic Info.

Model NO.

zf014

Material

High Chromium Alloy

Material Standard 1

ASTM A532

Raw Material

Chromium

Material Standard 2

DIN 1695

Material Standard 3

BS 4844

Material Standard 4

GB/T 8263

Transport Package

Wood Case

Specification

800mm*800mm*800mm

Trademark

zf

Origin

China

HS Code

8474900000

Production Capacity

1000 Tons Per Year

Product Description

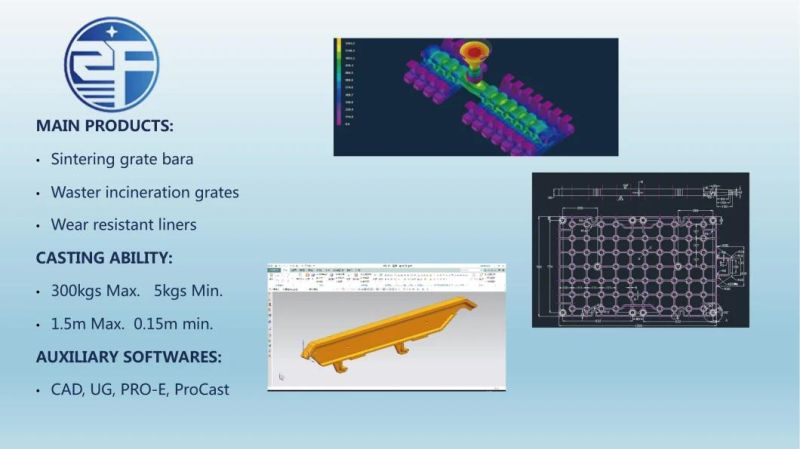

High Cr Alloy Steel Ball Mill, Grinding Parts, Liners

Widely used in mining industry, Quarrying & Aggregate, metallurgical industry, construction industry, chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, sandstone, quartz and so on.

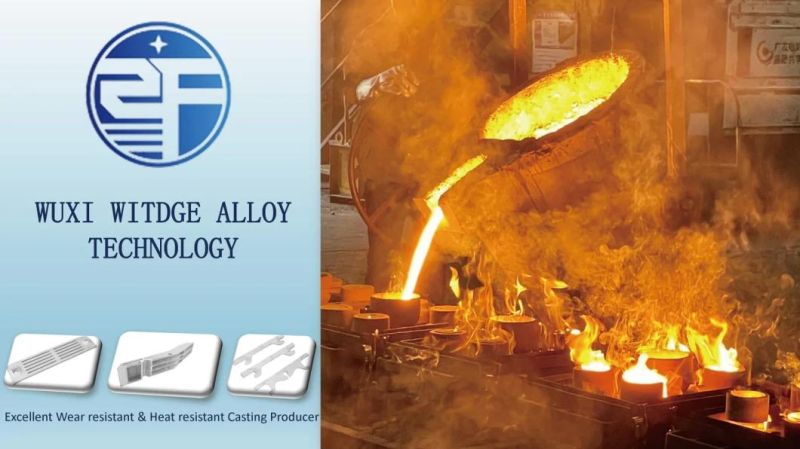

Witdge Alloy is recognized foundry that is known for producing high quality grate bars, insulation cover and sidewalls, mill liners, wear billets, wear plates. Our company has been manufacturing and producing these castings for many clients around the world. We work with design company and end users for the Iron Ore Pelletizing operations, aggregates operations, we have sufficient experience to create the finest products.

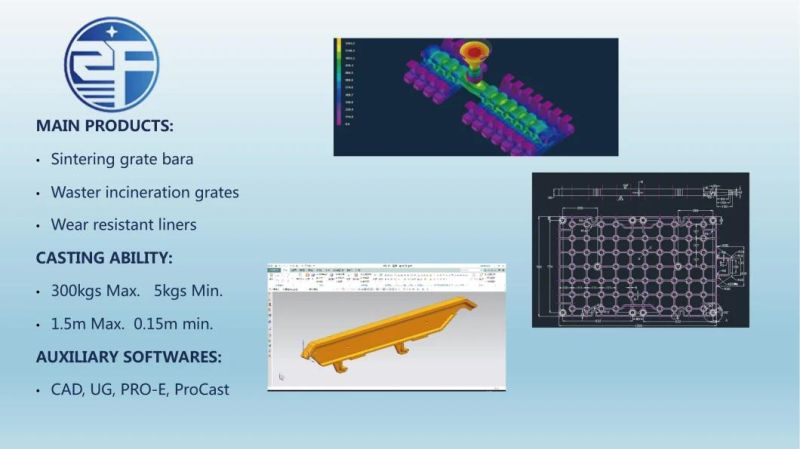

Major Products:

Waste Incineration Grate, Grate plate etc.

Grate bar, insulation cap, side wall, screen deck, grate, liner etc.

Wear resistant liner, squeeze parts, wear plate, hammer etc.

Heat treatment furnace tray, basket, wheel, track, fan, fixtures etc.

Years of partnership, Consistent quality control from subcontractors:

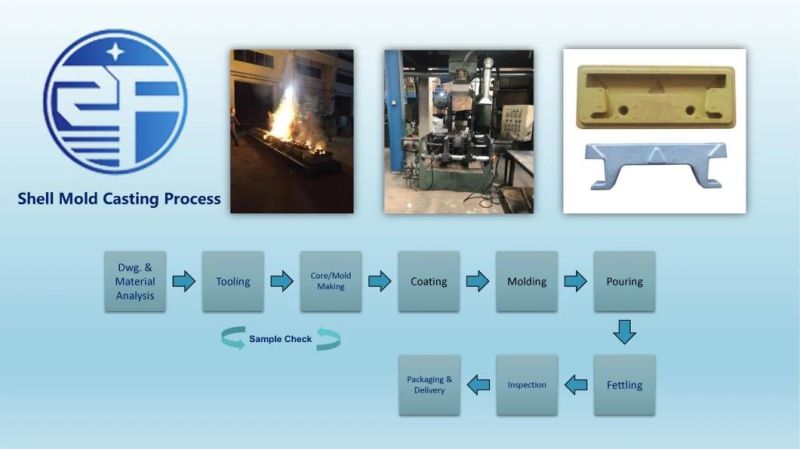

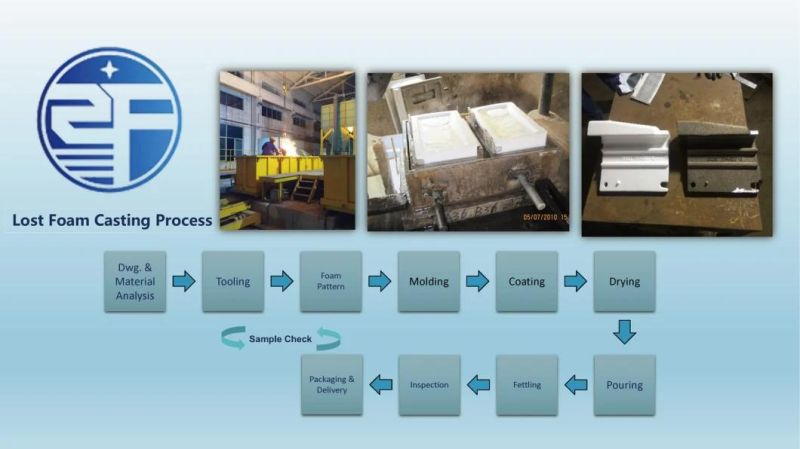

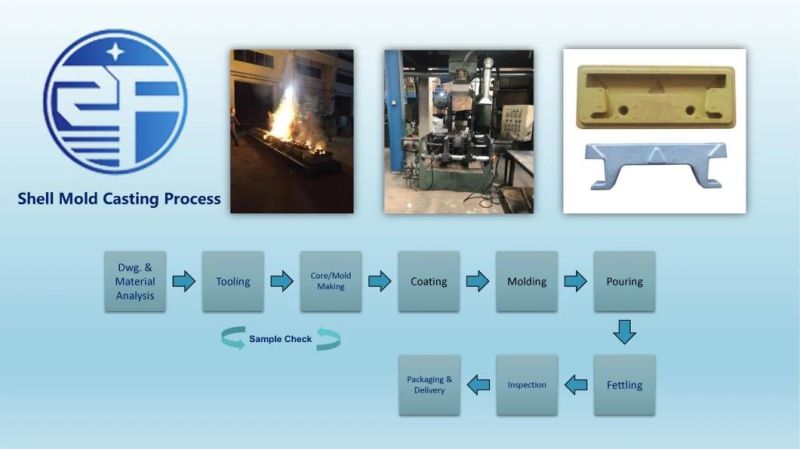

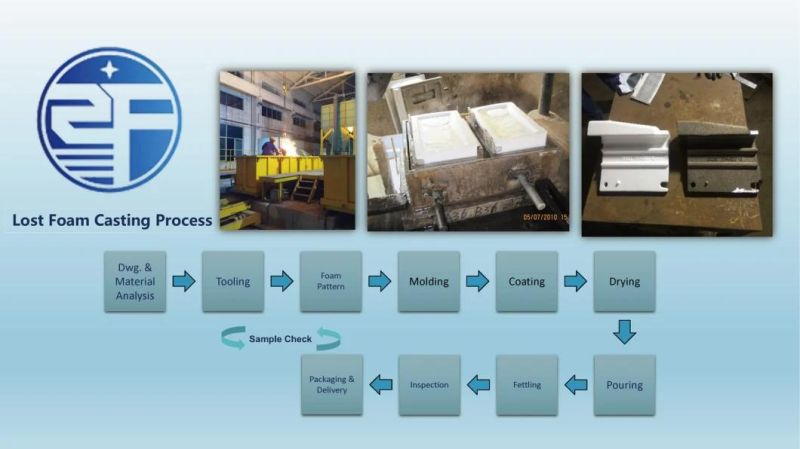

Common machining methods include turning, milling, grinding, boring, drilling, line cutting.

Common heat treatment methods include annealing, normalizing, quenching, tempering.

FAQ

FAQ

Q:Are you a trading company or manufacturer?

A: Witdge Alloy is an industrial with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:payment terms are negotiable.

Q:Can I have my own logo on the product?

A:we can apply your own logo on the products according to your drawings.