500 Mesh Gypsum Calcium Carbonate Limestone Kaolin Stone Powder Making Machine Pulverizer

Shanghai Clirik Machinery Co., Ltd.- Type:Stone Pulverizer

- Motor Type:AC Motor

- Motor Power:5.5KW

- Rotationl Speed:20-22r,min

- Application:Mine

- Materials:Stone

Base Info

- Model NO.:HGM

- Condition:New

- Warranty:1 Year

- After-sales Service:Technical Support

- After Sale:Abroad Engineer

- Color:as Request

- Power:Kw

- Name:Stone Pulverizer

- Price:Negotiable and Reasonable

- Transport Package:Wooden Box

- Specification:iso9001&ce

- Trademark:Clirik

- Origin:Shanghai

- HS Code:84742090

- Production Capacity:50 Set Per Month

Description

Product OverviewUltra fine pulveriser which we also called super fine pulverizer, micro powder pulverizer, because they can produce 2500 mesh powder.

Ultra fine pulveriser is for super-fine grinding materials with hardness less than 6 in Moh's scale and humidity less than 6 percent such as kaolin, limestone, basalt, calcite, marble, talcum, barite, gypsum, dolomite, bentonite mud, mica, pyrophyllite, sepiolite, carbon black, diatomite, graphite, alunite, fluorite, potassium feldspar, phosphorite, pigment, up to 200 kinds.

Ultra fine pulveriser, the granularity (or final size) of the finished products can be freely adjusted between 325-3000meshes (0.045-0.0057mm), and the capacity (ton/hour) ranges from 0.4T/H to 12T/H depending on the final size and the grinding materials.

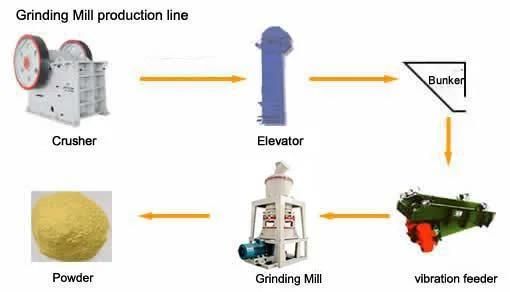

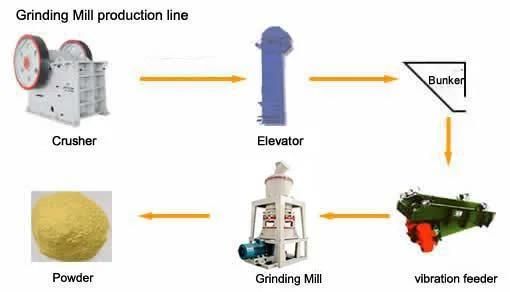

The whole set ultra fine pulveriser consists of

1). Hammer crusher, bucket elevator, storage hopper, vibrating feeder,

2). Main unit, inverter classifier, cyclone collector, pulse deduster system,

3). High pressure positive blower, air compressors and electrical control systems.

Working Principle

Working Principle of ultra fine pulveriser

1.The crusher will crush the big materials into small ones, and then the elevator will send them to the hopper.

2.The vibrating feeder will send the materials to the middle of first dial evenly.

3.The motor of main equipment drives the main shaft and dial through reducer, and the dial drives numbers of rollers moving in the ring channels via pins.

4.The materials will be driven to the edge of dial by centrifugal force and fall down into the ring, crushed and grinded by roller, and become powder after production of three rings.

5.The high pressure centrifugal blower will inhale air from outside and bring the crushed materials to classifier.

6.The rotating turbo in the powder collector will make the coarse materials return to the mill and regrounded, while the fineness will mix with the air and go into the cyclone and be discharged in the discharge bin, which is at the bottom of it.

7.The air, which mixed with very little fineness, will be purified by impulse duster and discharged by blower and muffler.

Product Advantage

Features of Clirik ultra fine pulveriser

1. The ultra fine pulveriser is high efficient (twice as much as jet mill, mixing grinder and ball mill)

2. The spare parts of ultra fine pulveriser can serve much longer time (2-3 times longer than that of impact mill or turbo mill.

3. High safety and reliability of the ultra fine pulveriser (no rolling bearings and screws in the grinding cavity, so no problems caused by the wear of bearings or screws).

4. The ultra fine pulveriser are characterized by high fineness (final size: 325-3000 mesh, D97<5 micron)

5. Environment-friendly.

PRODUCT SPECIFICATIONS

Model HGM80 HGM90 HGM100 HGM125 HGM168L Ring Diameter

(mm) 800 900 1000 1250 1680 Ring Number

(PCS) 3 3-4 4 4 4 Roller Number

(PCS) 18-21 24-29 28-36 30-44 30-40 Main Shaft Speed

(r. p. min) 230-240 200-220 180-200 135-155 120-130 Input Size

(mm) ≤10 ≤10 ≤15 ≤15 ≤20 Finished Size

(um/mesh) 74-5

(200-2500) 74-5

(200-2500) 74-5

(200-2500) 100-6

(150-2000) 100-9

(150-1500) Capacity

(t/h) 0.4-4.5 0.6-6.5 1-9 2-16 3.8-30 Outlet Size

L*W*H (m) 13.9*4*6.2 14.7*4.8*7.2 18*4.6*8.6 14*9*10.25 26.3*7.5*11.9

Note: This specification is just referencing, any changes are subject to the products.

Company Profile

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china as a professional enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

So far, we have established a whole production chain, the products covermicro powder grinding mill, high pressure grinding mill,Europe an version coarsegrinding mill, hammer crusher, jaw crusher, screw conveyor, bucket elevator and so on. They are widely used in the industry of mining, construction materials, chemicals, metallurgy, transportation, hydraulic engineering and so on.Specially we independently developed HGM micro powder grinding mill, which are not only renowned in domestic market, but also have been sold widely in Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, Oceania, and America, etc.We still insist on the communication and cooperation with prestigious scientific research institutions from both home and abroad to make our development ability always is in the domestic front. Based on the principle of constant innovation and quality guarantee, customer foremost, we are able to provide our customers not only the highest quality products at the most favorable price but also the most reasonable solution, such as the selection of the equipment,optimized process configuration and a full range of technical support, therefore we always follow your steps, pursue your value and achieve your benefit.

So far, we have established a whole production chain, the products covermicro powder grinding mill, high pressure grinding mill,Europe an version coarsegrinding mill, hammer crusher, jaw crusher, screw conveyor, bucket elevator and so on. They are widely used in the industry of mining, construction materials, chemicals, metallurgy, transportation, hydraulic engineering and so on.Specially we independently developed HGM micro powder grinding mill, which are not only renowned in domestic market, but also have been sold widely in Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, Oceania, and America, etc.We still insist on the communication and cooperation with prestigious scientific research institutions from both home and abroad to make our development ability always is in the domestic front. Based on the principle of constant innovation and quality guarantee, customer foremost, we are able to provide our customers not only the highest quality products at the most favorable price but also the most reasonable solution, such as the selection of the equipment,optimized process configuration and a full range of technical support, therefore we always follow your steps, pursue your value and achieve your benefit.

FAQ

1. What advantages does your micro powder machine, stone mill, powder grinding mill have?

The main advantage of our micro powder machine, stone mill, powder grinding mill over other kinds of mills is that you can grind a friable or crystalline material to 5 - 74 microns average particle size and classify in a very narrow particle size range at the same time. There are no moving parts to wear out or generate heat in our mill and no screens to plug or be punctured.

2. Can you guarantee the quality of your micro powder machine, stone mill, powder grinding mill?

We have passed CE&ISO9001:2008, and our crushers have been exported to Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, Oceania, America, etc.

3.How many years have you been manufacturing the machine?

8 years. Since the foudation of our company, we have been manufacturing the machine, which updated many times, now the machine runs stable and of high quality

Any inquiries of our machine, stone mill, powder grinding mill will be highly regard and we will give you the best quotation ASAP. Your satisfaction is our final ann forever pursuit.

Please fill in your need products and your message and do not forget email and/or phone if you like to be contacted.

We look forward to your inquiries!

Shanghai Clirik Machinery CO., LTD.

Ultra fine pulveriser is for super-fine grinding materials with hardness less than 6 in Moh's scale and humidity less than 6 percent such as kaolin, limestone, basalt, calcite, marble, talcum, barite, gypsum, dolomite, bentonite mud, mica, pyrophyllite, sepiolite, carbon black, diatomite, graphite, alunite, fluorite, potassium feldspar, phosphorite, pigment, up to 200 kinds.

Ultra fine pulveriser, the granularity (or final size) of the finished products can be freely adjusted between 325-3000meshes (0.045-0.0057mm), and the capacity (ton/hour) ranges from 0.4T/H to 12T/H depending on the final size and the grinding materials.

The whole set ultra fine pulveriser consists of

1). Hammer crusher, bucket elevator, storage hopper, vibrating feeder,

2). Main unit, inverter classifier, cyclone collector, pulse deduster system,

3). High pressure positive blower, air compressors and electrical control systems.

Working Principle

Working Principle of ultra fine pulveriser

1.The crusher will crush the big materials into small ones, and then the elevator will send them to the hopper.

2.The vibrating feeder will send the materials to the middle of first dial evenly.

3.The motor of main equipment drives the main shaft and dial through reducer, and the dial drives numbers of rollers moving in the ring channels via pins.

4.The materials will be driven to the edge of dial by centrifugal force and fall down into the ring, crushed and grinded by roller, and become powder after production of three rings.

5.The high pressure centrifugal blower will inhale air from outside and bring the crushed materials to classifier.

6.The rotating turbo in the powder collector will make the coarse materials return to the mill and regrounded, while the fineness will mix with the air and go into the cyclone and be discharged in the discharge bin, which is at the bottom of it.

7.The air, which mixed with very little fineness, will be purified by impulse duster and discharged by blower and muffler.

Product Advantage

Features of Clirik ultra fine pulveriser

1. The ultra fine pulveriser is high efficient (twice as much as jet mill, mixing grinder and ball mill)

2. The spare parts of ultra fine pulveriser can serve much longer time (2-3 times longer than that of impact mill or turbo mill.

3. High safety and reliability of the ultra fine pulveriser (no rolling bearings and screws in the grinding cavity, so no problems caused by the wear of bearings or screws).

4. The ultra fine pulveriser are characterized by high fineness (final size: 325-3000 mesh, D97<5 micron)

5. Environment-friendly.

PRODUCT SPECIFICATIONS

(mm)

(PCS)

(PCS)

(r. p. min)

(mm)

(um/mesh)

(200-2500)

(200-2500)

(200-2500)

(150-2000)

(150-1500)

(t/h)

L*W*H (m)

Note: This specification is just referencing, any changes are subject to the products.

Company Profile

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china as a professional enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

So far, we have established a whole production chain, the products covermicro powder grinding mill, high pressure grinding mill,Europe an version coarsegrinding mill, hammer crusher, jaw crusher, screw conveyor, bucket elevator and so on. They are widely used in the industry of mining, construction materials, chemicals, metallurgy, transportation, hydraulic engineering and so on.Specially we independently developed HGM micro powder grinding mill, which are not only renowned in domestic market, but also have been sold widely in Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, Oceania, and America, etc.We still insist on the communication and cooperation with prestigious scientific research institutions from both home and abroad to make our development ability always is in the domestic front. Based on the principle of constant innovation and quality guarantee, customer foremost, we are able to provide our customers not only the highest quality products at the most favorable price but also the most reasonable solution, such as the selection of the equipment,optimized process configuration and a full range of technical support, therefore we always follow your steps, pursue your value and achieve your benefit.

So far, we have established a whole production chain, the products covermicro powder grinding mill, high pressure grinding mill,Europe an version coarsegrinding mill, hammer crusher, jaw crusher, screw conveyor, bucket elevator and so on. They are widely used in the industry of mining, construction materials, chemicals, metallurgy, transportation, hydraulic engineering and so on.Specially we independently developed HGM micro powder grinding mill, which are not only renowned in domestic market, but also have been sold widely in Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, Oceania, and America, etc.We still insist on the communication and cooperation with prestigious scientific research institutions from both home and abroad to make our development ability always is in the domestic front. Based on the principle of constant innovation and quality guarantee, customer foremost, we are able to provide our customers not only the highest quality products at the most favorable price but also the most reasonable solution, such as the selection of the equipment,optimized process configuration and a full range of technical support, therefore we always follow your steps, pursue your value and achieve your benefit.

FAQ

1. What advantages does your micro powder machine, stone mill, powder grinding mill have?

The main advantage of our micro powder machine, stone mill, powder grinding mill over other kinds of mills is that you can grind a friable or crystalline material to 5 - 74 microns average particle size and classify in a very narrow particle size range at the same time. There are no moving parts to wear out or generate heat in our mill and no screens to plug or be punctured.

2. Can you guarantee the quality of your micro powder machine, stone mill, powder grinding mill?

We have passed CE&ISO9001:2008, and our crushers have been exported to Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, Oceania, America, etc.

3.How many years have you been manufacturing the machine?

8 years. Since the foudation of our company, we have been manufacturing the machine, which updated many times, now the machine runs stable and of high quality

Any inquiries of our machine, stone mill, powder grinding mill will be highly regard and we will give you the best quotation ASAP. Your satisfaction is our final ann forever pursuit.

Please fill in your need products and your message and do not forget email and/or phone if you like to be contacted.

We look forward to your inquiries!

Shanghai Clirik Machinery CO., LTD.