Casting Foundry Factory Crusher Wear Parts Spare Parts Supplier Price

Shanghai Duoling Watson Mining Equipment Co., Ltd.- After-sales Service:Available

- Warranty:Available

- Certification:ISO 9001:2008

- Standard:ASTM

- Surface Treatment:Polishing

- Manufacturing Process:Casting

Base Info

- Material:Alloy Steel

- Quality:High

- Application:for Jaw Crusher to Replace

- Teeth:Square

- Transport Package:Iron Frame

- Specification:Mn13Cr2, Mn18Cr2

- Origin:China

- HS Code:8474900000

- Production Capacity:10000ton Per Year

Description

Crusher type

Model

Spare parts

Cone crusher

HP100, HP200, HP300, HP400, HP500, HP4, HP5, GP100, GP200, GP300, GP550, GP11

Bowl liner, mantle

H2800, H3800, H4800, H6800, H7800, H8800, S2800, S3800, S4800, S6800

4FT.Standard, 4-1/4FT.Short head , 5-1/2FT.Standard

Features of cone crusher wear parts :

1) Material: high manganese steel:Mn13Cr2, Mn18Cr2, etc;

2) Use: Machinery in metal recovery smash, mine, metallurgy, chemical industry, cement, petroleum etc.

3) Production quality testing: High frequency infrared carbon & sulfur analyzer, Metallographic microscope, Machinery performance testing equipment, Hardness testing equipment, Ultrasonic inspection equipment

4) Easy installation: The anti-abrasion block is a semi-permanent part, which is easy for replacement.

Chemical composition of cone crusher wear parts

Code Elem

C

Mn

Si

Cr

Mo

P

S

ZGMn13-1

1-1.45

11-14

0.3-1

-

-

≤0.09

≤0.04

ZGMn13-2

0.9-1.35

11-14

0.3-1

-

-

≤0.09

≤0.04

ZGMn13-3

0.9-1.35

11-14

0.3-0.8

-

-

≤0.09

≤0.04

ZGMn13-4

0.9-1.3

11-14

0.3-0.8

1.5-2

-

≤0.09

≤0.04

ZGMn13-5

0.75-1.3

11-14

0.3-1

-

0.9-1.2

≤0.09

≤0.04

3-Introduction of Impact Crusher Parts

Blow bar Made by high wear-resisting material:high chrome cast-iron and high-manganese steel.

We manufacture an extensive range of wear and spare parts in China for the worlds most popular crushing brands.

Chemical composition of Impact Crusher Parts

NO.

chemical composition %

HRC

C

Si

Mn

Cr

Mo

Na

Cu

P

S

KmTBCr4Mo

2.5-3.5

0.5-1.0

0.5-1.0

3.5-4.5

0.3-0.5

-

-

≤0.15

≤0.10

≥55

KmTBCr9Ni5Si2

2.5-3.6

1.5-2.2

0.3-0.8

8.0-10.0

0-1.0

4.5-6.5

4.5-6.5

-

-

≥58

KmTBCr15Mo

2.8-3.5

≤1.0

0.5-1.0

13-18

0.5-3.0

0-1.0

0-1.0

≤0.10

≤0.06

≥58

KmTBCr20Mo

2.0-3.3

≤1.2

≤2.0

18-23

≤3.0

≤2.5

≤1.2

-

-

≥60

KmTBCr26

2.3-3.3

≤1.2

≤1.0

23-30

≤3.0

≤2.5

≤2.0

-

-

≥60

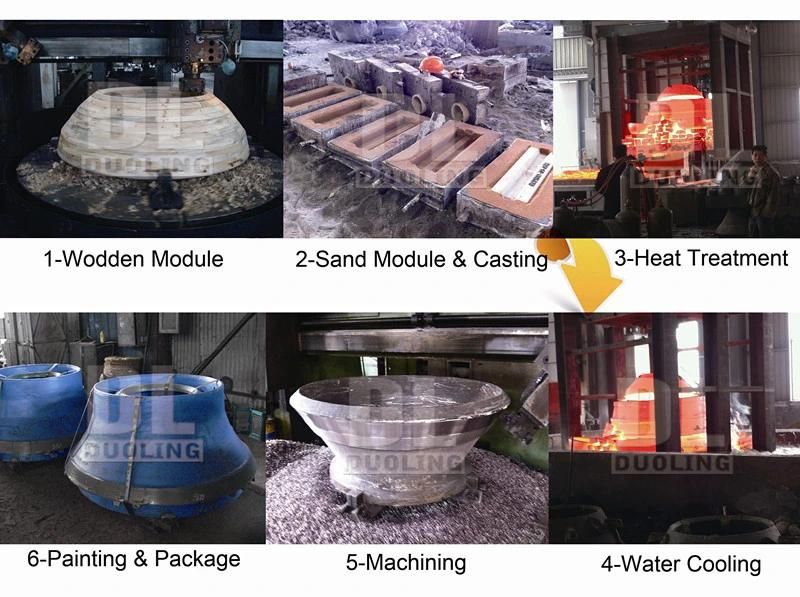

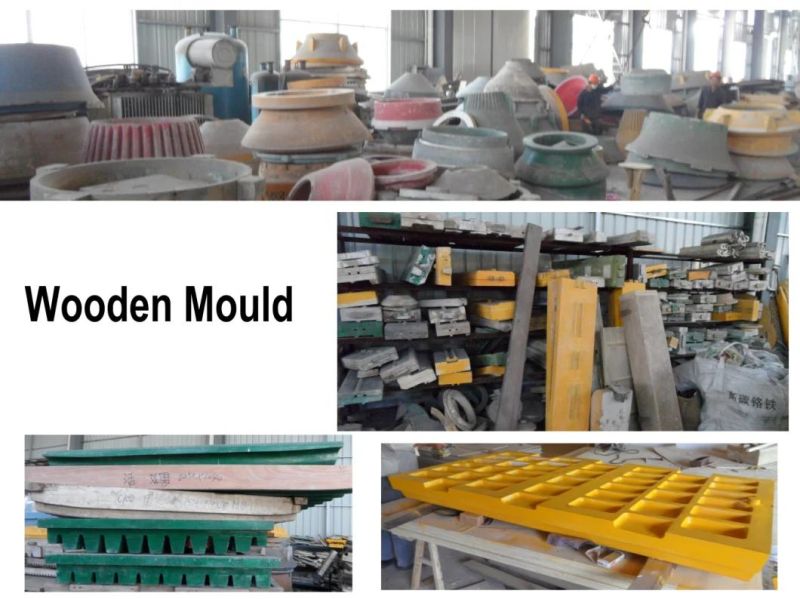

Production Process of Crusher Wear Parts