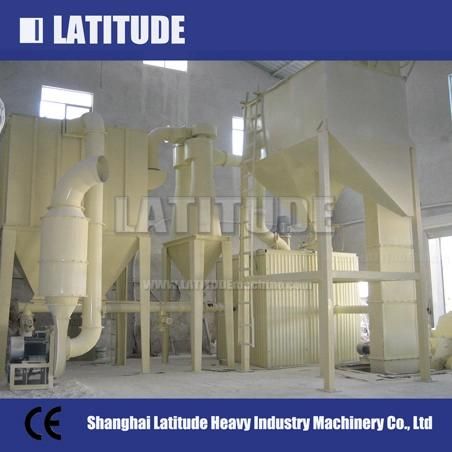

High Capacity Dolomite, Calcite, Barite, Talc Powder Three-Ring Micro Powder Mill ...

Shanghai Latitude Heavy Industry Machinery Co., Limited- Type:Ultrafine Powder Grinding Mill

- Motor Type:AC Motor

- Motor Power:It Is Different According to The Equipment Model

- Rotationl Speed:It Is Different According to The Equipment Model

- Application:Mine

- Materials:Nonmetal Materials

Base Info

- Model NO.:Ultrafine powder grinding Mill

- Condition:New

- Warranty:1 Year

- After-sales Service:One Year

- Product Fineness:600mesh-3000mesh

- Advantages:High Capacity, Easy Operation

- Feature:Saving Energy and Protecting Environmen

- Quality:Advanced Technology

- Wet or Dry Type:Dry Type Mill

- Classifiers:Air Classifiers Machine

- Environmental Protection Level:Good, with Pulse Dust Collector

- Operative Difficulty:Easy. 1-3 Worker, Centralized Control Room

- Maintenance Time Per Month:Half to One Day

- Occupied Area:90-150 M2

- Device Color:Customization

- Transport Package:Standard Container

- Specification:According to the product

- Trademark:Shanghai LATITUDE

- Origin:Shanghai, China

- HS Code:8474202000

- Production Capacity:1

Description

Basic Info.

Model NO. Ultrafine powder grinding Mill Condition New Warranty 1 Year After-sales Service One Year Product Fineness 600mesh-3000mesh Advantages High Capacity, Easy Operation Feature Saving Energy and Protecting Environmen Quality Advanced Technology Wet or Dry Type Dry Type Mill Classifiers Air Classifiers Machine Environmental Protection Level Good, with Pulse Dust Collector Operative Difficulty Easy. 1-3 Worker, Centralized Control Room Maintenance Time Per Month Half to One Day Occupied Area 90-150 M2 Device Color Customization Transport Package Standard Container Specification According to the product Trademark Shanghai LATITUDE Origin Shanghai, China HS Code 8474202000 Production Capacity 1Product Description

Three-ring Micro Powder Mill(ultrafine mill) is for super-fine grinding materials with hardness less than 6 in Moh's hardness scale and humidity less than 6 percent,such as kaolin, limestone, calcite, marble,talcum, barite ,garnet, gypsum, dolomite, bentonite mud,mica, pyrophyllite, sepiolite, diatomite, graphite, alunite, fluorite, potassium feldspar, phosphorite, pigment and so on. The granularity of the end products is 400-2800 meshes (0.044-0.0055mm).

It can be used for feeding materials with less than 3% in moisture and less than 10mm in feeding size. It enjoys extensive application in further processing of nonmetallic minerals with Mohs hardness rating of less than 5. It is also applied for ultra-fine grinding in variable industries such as chemical engineering, dyestuff, synthetic resin, coating materials, agricultural chemicals, starch, food as well as advanced technology in national defense. Excellent fineness, high output and low cost of processed products lead to enormous economic returns.

Input Size: 0-10mm

Output size: 400mesh-2800mesh

Capacity: 3-25TPH

Material:

It is suitable for processing nonmetallic minerals such as calcium carbonate, calcite, Kaolin, clay, barite, talc, gypsum, limestone, calcium oxide, bentonite, dolomite etc.

Mining, building materials, chemicals, metallurgy and other industries.

Product Advantages

1. Advanced grinding cavity design.High capacity and low consumption.

2. Easy installation of the whole equipment, little land coverage without large civil engineering projects. It can be put into production promptly after installation. The stable and reliable working performance allows continual production, high fineness of processed products, thus ensuring product quality.

3. High quality grinding media.Large range of fineness adjusting.

4. It has a fully integrated system. Its built-in classifying system is able to complete two procedures of ultrafine grinding and ultrafine classifying. It is also equipped with efficient cyclone separator or dust collecting system. The whole system works under negative pressure without dust spreading outwards, an ideal equipment for your clean production.

5. The whole grinding mill system with a compact structure could save factory space, with a lower foundation construction cost, it's a cost-effective investment.

Working Principle

General:

Crushing -- Grinding -- air classifier -- Collecting-- dust filter

Detailed:

After being crushed by hammer crusher, the big materials become small ones and they are sent to the storage bin by elevator. The electromagnetic vibrating feeder sends them to the middle of first dial evenly; the materials will be driven to the edge of dial by centrifugal force, and fall into the ring channels and are pressed, crushed and ground by the grinding rings and rolls. Then the materials fall into the second and third ring and crushed and ground.

The high pressure centrifugal blower inhales air from the outside and blow the materials which are ground in the third ring to powder Separator. The rotating turbo in the powder Separator makes the coarse materials return to the mill and reground, while the fineness mixes with the air and be drawn to the cyclone and be discharged from the discharging valve which is in the bottom of it. The air which mixed with very little fineness are purified by impulse dust catcher and discharged by blower and muffler.The product fineness(D97=3-35um) can be adjusted at any time according to customer demand.

Specifications - Technical Data

| Model | Ring Diameter (mm) | Ring Numbers (layer) | Roller Numbers (piece) | Main Shaft Speed (r.p.m) | Input Size (mm) | Output Size (mm/mesh) | Capacity (t/h) | Overall Dimension (L*W*H,m) |

| ZYM80 | 800 | 1+2 | 20 (6+7*2) | 230-240 | ≤10 | 0.074-0.005 (200-2500) | 0.4-5 | 13.9*4*6.2 |

| ZYM90 | 900 | 3+1 | 29 (3*7+8) | 200-220 | ≤10 | 0.074-0.005 (200-2500) | 0.6-7 | 14.7*4.8*7.2 |

| ZYM100 | 1000 | 2+2 | 28 (6*2+8*2) | 180-200 | ≤15 | 0.074-0.005 (200-2500) | 1-10 | 18*4.6*8.6 |

| ZYM125 | 1250 | 2+2 | 32 (7*2+9*2) | 135-155 | ≤15 | 0.1-0.006 (150-2000) | 2-16 | 14*9*10.25 |

| ZYM168 | 1680 | 2+2 | 44 (10*2+12*2) | 120-130 | ≤20 | 0.1-0.009 (150-1500) | 4-30 | 26.3*7.5*11.9 |

| Unit: KW | Main Unit | Classifier | Blower | Crusher | Bucket Elevator | Belt conveyor Feeder | Spiral Conveyor | Discharging Valeve | Air Compossor |

| ZYM80 | 75 | 18.5 | 45 | 18.5 | 3 | 2.2 | 3 | 0.75*2 | 11 |

| ZYM90 | 45*2 | 18.5 | 55 | 18.5 | 3 | 2.2 | 3 | 0.75+1.1 | 15 |

| ZYM100 | 132 | 30 | 75 | 18.5 | 4 | 2.2 | 3-4 | 1.1*2 | 22 |

| ZYM125 | 185 | 37-15*4 | 45*2-55*2 | 45 | 4 | 3 | 3*2 | 1.1*2 | 15*2-37 |

| ZYM168 | 315 | 18.5*5 | 75*2-90*2 | 45 | 7.5 | 3 | 5.5*2 | 0.75*2+1.5*2 | 55 |

Shanghai Latitude heavy industry machinery Co.,Ltd is one machinery manufacturer, We have a professional team. shanghai Latitude company provides a complete line of stone production& ,our team have more than 15 years experience in this field already.

1) Intelligent mining machinery and equipment

Cone Crusher, Jaw Crusher, impact crusher, screen, sand washer, hammer crusher, gyratory crusher and Artificial Sand Making Production Plant, Grinding Mill, Raymond Mill, Ball Mill manufacturer / supplier in China.

2) Superfine Powder Making Machinery and Intelligent powder conveying and packaging equipment.

Grinding Mill, Superfine Powder Making Machinery Grinding Mill, micro-powder Making Machinery, bucket elevator,valve port packer,ton bag fill and packing machine,Wind power separator,three-cylinder dryer,pulse dust collector/filter and so on.

3) Casting products

spare parts and wear parts for a wide range of crusher and Grinding mill parts, offering Bronze Bushing, Bronze Bowl Liner and Copper Seat for kinds of mining machine..

(1)Warranty:Every product issued shall enjoy a one-year/2000 working hour warranty period, during which we will repair or replace the defective parts free of charge if material or process defects occur and spare parts are in normal working condition.

(2)Spare parts:shanghai Latitude company is dedicated to provide our clients with genuine spare parts with the highest quality,exact fitness and appropriate function.with our global distributor network,you are guaranteed with fast deliveries and services, wherever you are,please submit your spare parts request to us,and list products name ,description of required parts.we guarantee that your request will be handled quickly and appropriately.

(3)Installation & Maintenance:shanghai Latitude company is able to provide with the overall installation of complicated machinery,allowing you to start the normal operation of construction machinery solutions.After installation,we will make inspection of the whole machine,operate equipment,and provide you with testing data reports of installation and operation.

(4)Training:shanghai Latitude company offer perfect facilities and comfortable environment and can provide training services to different users. The training sessions include product training, operation training, maintenance know-how, technical know-how training, standards, laws and regulations training and other training, all of which are tailored to fulfill your individual needs. Training programs can be conducted in our factory field, or at the client's site.

(5)Technical Advice: shanghai Latitude company can also help customers to coordinate with trained service personnel and provide you with detailed and extensive knowledge. Through our technical advice, your machine life can be significantly extended and sustained high capacity.

Which countries do you export to?

Asia: India, Philippines, Thailand, Burma, Vietnam, Bangladesh, Kazakhstan, Turkmenistan, etc.

Middle East: Saudi Arabia,UAE, Oman,Pakistan, Qatar, etc. Europe: Russia, Ukraine, Belarus, Bulgaria, etc.

Africa: South Africa, Kenya, Congo, Ethiopia, Nigeria, Ghana, Algeria, Senegal, etc.

South America: Brazil, Peru, Chile, Cuba, Mexico, etc. Oceania: Papua New Guinea, Australia, etc.

What is the proportion of your products exported?

45% of our products are exported to all over the world.

What is the payment term?

Payment term is negotiable and there will be favorable payment terms for long-term customers. TT, L/C, D/P, depending on the cooperation time, country and contract value.

What kind of logistic service do you supply?

A. Transportation: railway transportation, international through transport, including (international railway through transportation, Sea-rail intermodal through transportation, sea-land multimodal transportation. Means of transport : Container, LCL, FRC, ro-ro, bulk cargo, train carriage, truck, air plane.

B. Term: FOB,CIF, DAP, to door service, etc.

please contact with us ,get more information