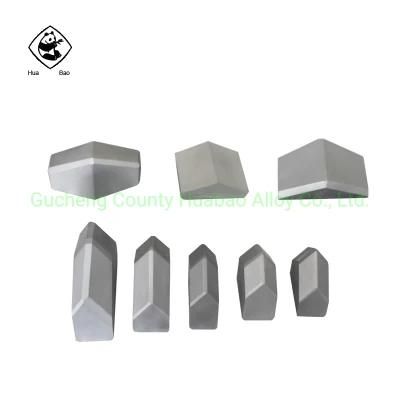

Cemented Carbide Cutting Tools Tungsten Carbide Shield Cutter Inserts

Gucheng County Huabao Alloy Co., Ltd.- Certification:SGS

- Surface Treatment:Polished or Blank

- Manufacturing Process:Forging

- Material:Tungsten Carbide Cobalt

- Grade:K10,K20,K30,K40,P10,P20,Yg6,Yg6X,Yg8,Yt5,Yt15

- Advantage:Excellent Wear Resistant and High Hardness

Base Info

- Model NO.:Cutter

- Delivery:15-20 Days After Receive Your Payment

- Surface Finishing:Polished or Ground

- Color:Iron Grey

- Using Purpose:Tips for Brazing Tools

- Wc+Co Powder:100% Virgin Material

- Trial Order:Accepted

- Transport Package:Inner Package with Box,Outer Package with Wooden C

- Specification:Tips

- Trademark:hua bao

- Origin:Hebei China

- HS Code:8208101900

- Production Capacity:5000 Mt Per Year

Description

Basic Info.

Model NO. Cutter Delivery 15-20 Days After Receive Your Payment Surface Finishing Polished or Ground Color Iron Grey Using Purpose Tips for Brazing Tools Wc+Co Powder 100% Virgin Material Trial Order Accepted Transport Package Inner Package with Box,Outer Package with Wooden C Specification Tips Trademark hua bao Origin Hebei China HS Code 8208101900 Production Capacity 5000 Mt Per YearProduct Description

Tungsten Carbide Shield Cutting Tools and Driving Cutter

1. Materials Specification:

| Grades | ISO Grade | Chemical Composition | Density (g/cm3) | HRA | T.R.S (N/mm2) |

| YG4C | 96%WC, 4%Co | 15.00 | 89.5 | 1800 | |

| YG6 | K20 | 94%WC, 6%Co | 14.80 | 89.5 | 1700 |

| YG8 | K20-K30 | 92%WC, 8%Co | 14.70 | 88.5 | 2300 |

| YG8C | K30 | 92%WC, coarse | 14.70 | 88.0 | 2300 |

| YG9C | YK20 | 94%WC, 6%Co | 14.45 | 87.0 | 2400 |

| YG11C | 89%WC, 11%Co | 14.40 | 86.5 | 2450 | |

| YG13C | 87%WC, 13%Co | 14.30 | 86.0 | 2500 | |

| YG15 | K40 | 85%WC, 15%Co | 14.00 | 86.5 | 2500 |

| YG16 | 84%WC, 16%Co | 14.10-14.30 | 87.5 | 2400 | |

| YG20 | 80%WC, 20%Co | 13.40-13.70 | 85.0 | 2254 |

2, Our Advantages:

1. The Cemented carbide tools are manufactured from our premium virgin grade.

2. A tungsten carbide and cobalt combination that allow the highest wear resistance and fracture toughness possible in most application.

3. Our heat treating process has been perfected to maintain carbon control and porosity,

4. Helping to eliminate premature breakage and wear.

5. Professional suggestion grade on products

6. Good wear resistance, excellent anti-impact and anti-knocking properties.

7. Various dimensions and shapes of tungsten carbide tools are available here

Size and Drawing,--Cutomized design is OK to make

3. Main Product

1) Tungsten carbide buttons/teeth,

2) Tungsten carbide PDC substrates,

3) Tungsten carbide rods/bars,

4) Tungsten carbide brazed tips,

5) Tungsten carbide balls,

6) Tungsten Carbide Plates,

7) Tungsten Carbide Non-Standard products, etc..