Water Well 168 mm Casing Gse- Odex140 Odex 140 Drilling System

Guizhou Sinodrills Equipment Co., Ltd.- Certification:ISO 9001:2008

- Manufacturing Process:Forging

- Material:Alloy Steel

- Product Name:Odex 90 Casing Drilling System Odex90 Drill Bit

- Max. Casing O.D:168 mm

- Min. Casing I.D:152 mm

Base Info

- Model NO.:ODEX 140

- Button Shape:Ballistic, Spherical

- Shank:DHD 350

- Application 1:Geothermal Well Drilling, Water Well Drilling

- Application 2:Foundation Work, Anchoring

- Rock Formation:Unconsolidated

- Other Name:Odex Bits, Overburden Drill Bit, Odex DTH Bit

- 1:Odex Rock Drilling Bit

- Transport Package:Plywood Box

- Specification:ODEX140

- Trademark:SINODRILLS

- Origin:China

- HS Code:8207199000

- Production Capacity:10000,Month

Description

Basic Info.

Model NO. ODEX 140 Button Shape Ballistic, Spherical Shank DHD 350 Application 1 Geothermal Well Drilling, Water Well Drilling Application 2 Foundation Work, Anchoring Rock Formation Unconsolidated Other Name Odex Bits, Overburden Drill Bit, Odex DTH Bit 1 Odex Rock Drilling Bit Transport Package Plywood Box Specification ODEX140 Trademark SINODRILLS Origin China HS Code 8207199000 Production Capacity 10000/MonthProduct Description

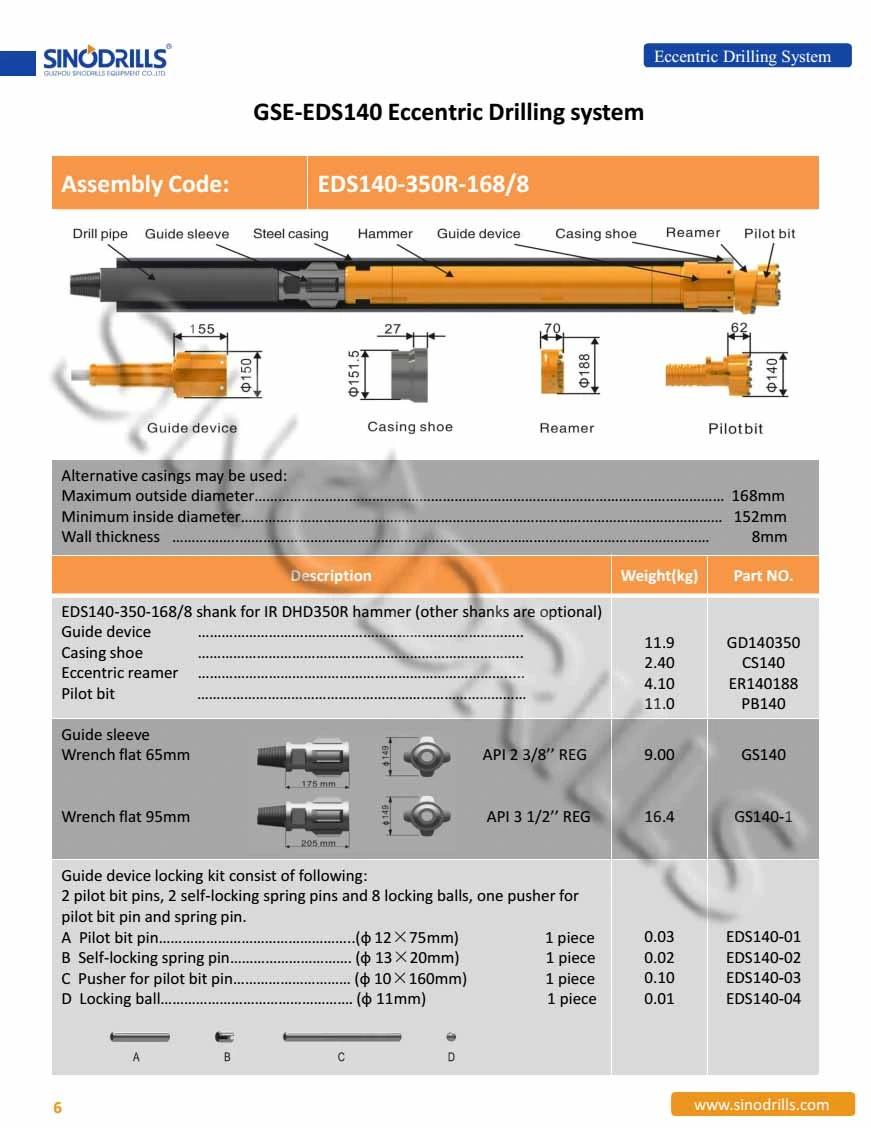

SINODRILLS Eccentric overburden casing drilling system:

Eccentric casing drilling system is today's preferred method for drilling in difficult ground conditions, for example, where there are boulders or loose formations.EDS is the most economical solutions because its ingenious reaming wing the bit is retrievable can be used at the next hole. This is particularly design for shallow holes, as is often the case in water well drilling, geothermal wells and for shallow micro-piling work. EDS is ideal for short holes in consolidated overburden. The component of Eccentric system consists of Pilot bits, Reamer bits, Guide device and casing shoe.

When drilling, the reamer bit will rotate out to enlarge the hole which enough for the casing tube slide down behind the reamer. When reached required depth, the drill pipe will drill to the reverse direction and the reamer bit will retract, it is allowing the whole drilling system to pass through the casing. odex dth bit

The below size of Eccentric systems which are available, and the special design is upon customer's requirement:

Eccentric 90, Eccentric 114, Eccentric 140, Eccentric 165, Eccentric 190 and Eccentric 240

Application

- Geothermal well drilling

- Water well drilling

- Pipe roofing(umbrella arch drilling)

- Foundation work

- Anchoring etc.

A multitude of applications, From anchoring to slope stabilization, from micropiling to curtain grouting, from tunnel forepoling to marine piling applications. Wherever the ground is unstable, drilled casings offer the basis of an excellent solution.

Product photos

Buyer's feedback

Related products

| Hammer size | Shank type | Recommended DTH bits diameter | Working pressure |

| 3.5"/3" DTH hammer | COP32, COP34, DHD3.5, MISSION30 | 90mm - 105mm | 8-30 bar |

| 4" DTH hammer | DHD340, QL40, MISSION40, SD4, TD40, COP44, COP44 GOLD, COP42 | 110mm - 130mm | 8-30 bar |

| 5" DTH hammer | DHD350, QL50, MISSION50, SD5, TD50, COP54, COP54 GOLD | 134mm - 152mm | 8-30 bar |

| 6" DTH hammer | DHD360, QL60, MISSION60, SD6, TD60, COP64, COP64 GOLD, COP66 | 152mm - 203mm | 8-30 bar |

| 8" DTH hammer | DHD380, QL80, MISSION80, SD8 | 203mm - 305mm | 8-30 bar |

| 10" DTH hammer | SD10, Numa100 | 240mm - 311mm | 17-24 bar |

| 12" DTH hammer | DHD112, SD12, QL120, Numa120 | 311mm - 445mm | 17-24 bar |

What we do

| Down The Hole rock drilling tools | Top hammer rock drilling tools | Self drilling anchor system | Drag bits |

|  |  |  |

| - DTH hammers - DTH bits - DTH drill pipes - Odex and Symmeric drilling | - Taper drill bits and rods - Threaded buttons bits and drill rods - Shank adapters - Couplings | - Threaded hollow anchor bars. - Accessories ( drill bit, coupling, nut, plate, centralizer etc.) | - Step drag bit (3 wings, 4 wings ) - Chevron drag bit (3 wings, 4 wings ) |

| Application | Application | Application | Application |

| Mining, quarry, water well drilling, geothermal drilling, construction foundation work etc. | Mining, quarry, construction foundation work | tunnel roof support, slop stability, Soil nailing, rock bolting, micropile etc. | mining, water well drilling, geothermal drilling etc. |

Our Workshop

FAQ

Q1: Are you a manufacturer?

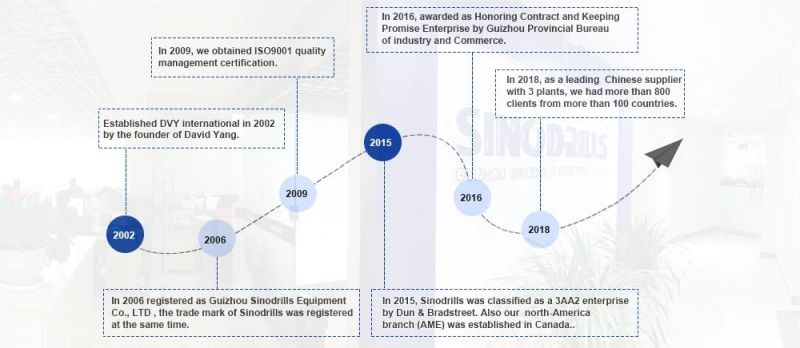

A1: Yes, we own 2 plants to manufacture various drilling products, including TH (top hammer) drilling products, DTH drilling products, self-drilling anchor systems and drag bits.

So we are a one-stop supplier of full range of rock drilling products.

Q2: What qualifications do you have?

A2: Till 2016, we have following qualifications:

- ISO 9001:2008 quality management system;

- 3AA2 credit rating by Dun & Bradstreet;

- Honoring Contract and Keeping Promise Enterprise by AIC;

- EC examination certificate for self-drilling anchor bars;

- 2 invention patents & 6 utility patents.

Q3: Where did you export and what was your annual export amount?

A3: Till 2020 we have exported to 105 countries and our average annual export amount within recent 3 years is 30 million USD.

Q4: What kind of payment terms do you offer and what is your best payment terms?

A4: We offer different payment terms, including T/T, D/A, D/P, L/C and O/A, etc. Our best payment terms is 120 days after shipping date for our distributors and sole distributors.

Q5:Do you offer warranty on your products?

A5: Yes, for different products we offer different warranty that cover all manufacturing defects in materials and workmanship. The longest period of warranty is 2 years after shipping date.

Q6: Do you offer OEM service?

Q6: Yes, we offer OEM service if you have regular requirement.