PCD/PDC Diamond Enhanced Cutting Tool for Underground Mining Diamond Drilling Mining Bits

WUHAN REETEC DIAMOND CO., LTD.- Certification:ISO 9001:2008

- Standard:GB

- Surface Treatment:Sand Blast

- Manufacturing Process:Forging

- Material:Alloy Steel

- Tip Material:Diamond Button

Base Info

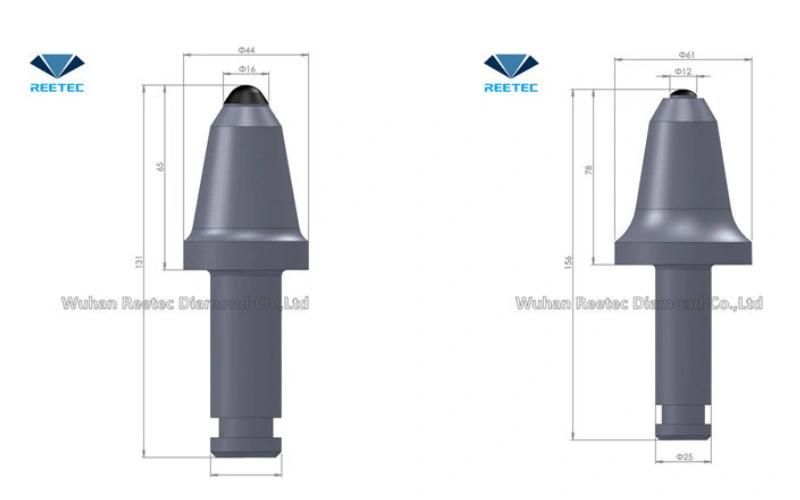

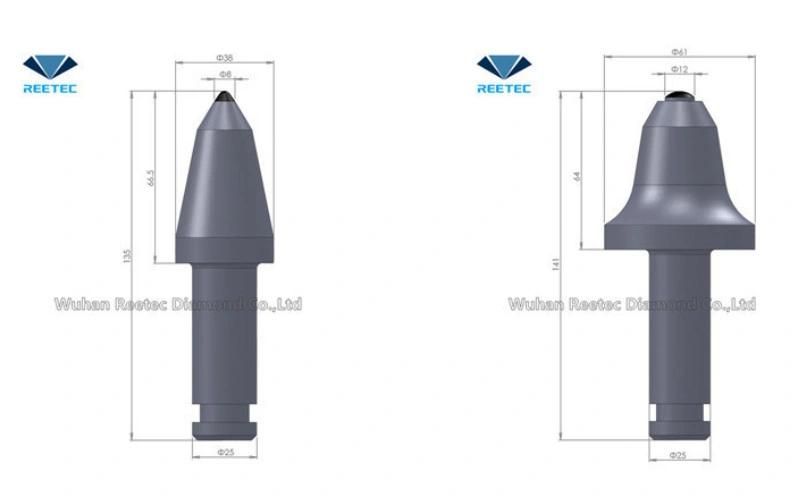

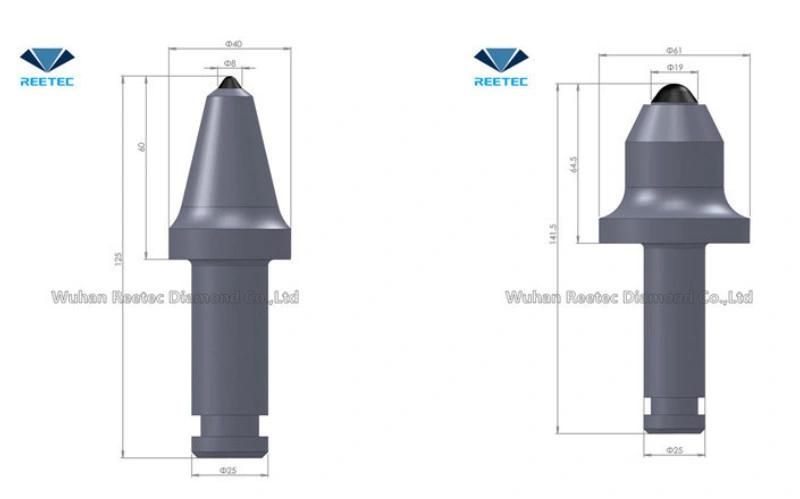

- Model NO.:25mm, 30mm, 35mm

- Equipments:Underground Miner, Longwall Miner, Continuous Mine

- Applications:Hard Rock, Abrasive Rock

- Body Protection:Hard Face

- Transport Package:Box

- Specification:400*300*250mm

- Trademark:REETEC

- Origin:China

- HS Code:8207191000

- Production Capacity:200000 Pieces,Year

Description

Advantages:

According to the field application results we have obtained, compared with traditional carbide pick, diamond pick has the following advantages:

- The service life of diamond pick increases more than 5 times.

- Tool consumption decreases more than 30%.

- The production efficiency of the operation is increased by more than 20%;

- Reduce the frequency of tool replacement and reduce the labor intensity of workers.

Clients' Applications

Diamond enhanced mining picks

Packing and shipping

Company Information

Wuhan Reetec Diamond Co., Ltd. (Wuhan Reetec for short) is a specialized company engaged in diamond composite materials research and development, design and manufacture, the main products PDC cutters and top dome PDC inserts are widely used in petroleum geological drilling and exploration, coal mining, road and bridge engineering excavation, as well as other areas of abrasion resistant tools.

With strong supports from the R&D system of Kingdream Public Limited Company(Kin gdream for short), Wuhan Reetec Diamond Co., Ltd was established and registered in Wuhan East Lake New Tech Development Zone on December 28, 2002. In 2006, Reetec passed ISO9001-2000 QMS Certification. In 2008, The Company was recognized as a National Hi-Tech. Enterprise, and passed ISO 9001-2008 QMS Renewal Certification in 2010.

Diamond Picks Characters:

1.The wear resistance of PDC: 30-40 times than tungsten carbide tip. , especially suitable hard and abrasive rock formation

2.The service life :8-10 times more than carbide picks, greatly reducing downtime and maintenance

3. Hardfacing: used a new material (Cerame),the hardness HRC 63-70 ,to limit Tip undermining and to protect holder tools.

4. Pick body :higher grade steel ,heat treated up to 55-57 HRC hardness

5. The impact strength : greater than 400 Joule

FAQ

| Type of Company | Manufacturer |

| Founded in | 2002 |

| Sample Order | Accept |

| OEM | Available |

| Quality Control | Each product will be inspected in strict procedure before delivery |

| After-sales Service | If quality problem, goods can be return or replaceable. |

| Payment Terms | 50% in advance by T/T, delivery against balance |

| Delivery Time | 20-45 days after receipt |

| Packing | Plastic box |

| Factory Location | Wuhan, Hubei Province |

Contact