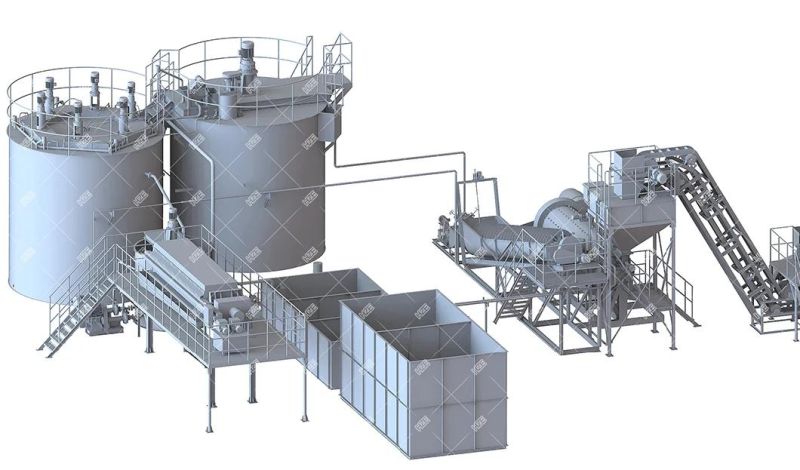

Small Scale Hard Rock and Alluvial Gold Mining Processing Equipment

Yantai Huize Mining Engineering Co., Ltd.- Function:Gold Recovery

- Type:Gold Mining Equipment

- Main materials:Steel

- Installation:Portable, Bobile, Fixed

- Capacity:1-50 tph

- Application:Gold Mines

Base Info

- Driving:Electric Motor, Diesel Engine

- Supply Voltage:127,220V,220,380V,230,400V,240,415V,400,690V

- Gold Recovery Rate:65-99%

- Processed Raw Materials:Placer, Alluvial,Eluvial, Hark Rock, Tailings

- Installation Position:Indoor, Outdoor

- Warranty period:365 Days

- Customization:Acceptable

- Color:Multi, Selectable

- Certificate:ISO9001:2015, ISO14004:2015, SGS:QIP-ASR205018

- Transport Package:Containerized

- Specification:Small, Medium, Large Scale

- Trademark:HZE

- Origin:China

- HS Code:8474100000

- Production Capacity:1000

Description

The concentrate is mixed with borax after iron removal then it is smelted in the flame oven to cast bullions.

The concentrate is further ground and mixed with mercury after iron removal, and the amalgam is distilled in a closed retort then it is smelted by the propane torch to get the ingot.

The concentrate is mixed with borax after iron removal then it is smelted in the medium frequency induction smelting furnace to cast bullions.

SOLUTIONS

HZE fully understands the details of each client's gold deposit and fully communicates with the client to customize the most suitable scheme. HZE provides one-stop service including process design, equipment manufacturing, installation, commissioning and training, so as to help the clients to produce gold with advanced technology and reliable equipment under the condition of saving investment, realize the goals of environmental friendly, energy saving, consumption reduction and high profit.

ADVANTAGES

Small modular plants and equipment are mobile for easy moving from one mining area to another site.

Small modular plants and equipment are lightweight and compact in size. The equipment can be driven by motor or diesel engine, which is convenient to use in remote areas.

Free of civil engineering investment or little investment in civil engineering, quick site installation, low investment costs and fast recovery of funds.

Compared with the mercury amalgamation, the gold recovery rate is increased by more than 10%, and it is conducive to environment and human health.

With good reliability and simple operation, small scale artisanal miners are easy to become experts in gold mining and processing industries.

The small plants can be used as pilot plants for large-scale projects or as a processing plants during prospecting.

FAQ

1.What is the main business scope of your company?

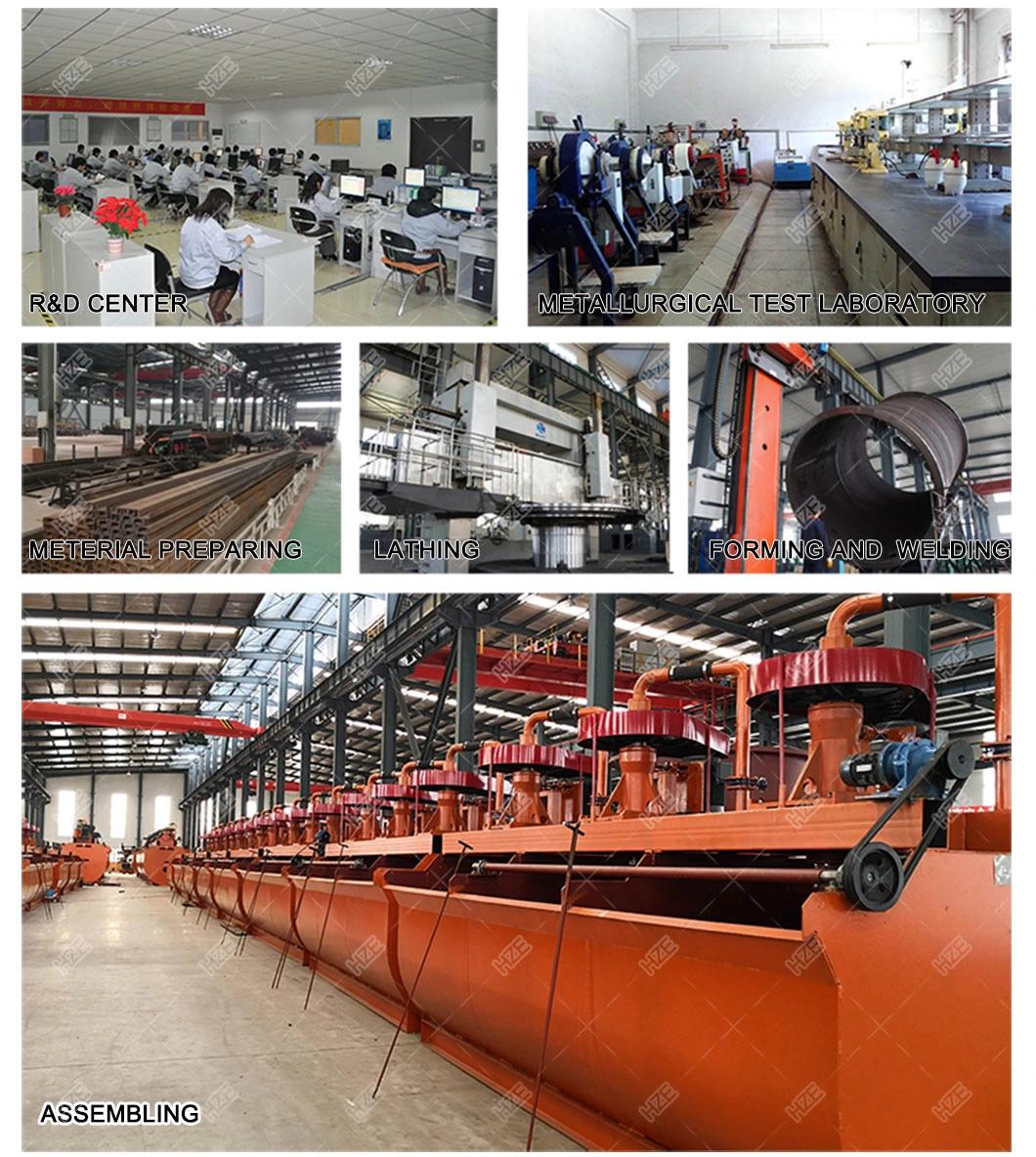

HZE is a company with R&D center, design institute, manufacturing factories, installation and commissioning teams.Our customers are in the mining and mineral processing fields.Our major businesses include mineral processing EPC (engineering, procurement and construction), project consultation, engineering design, mineral processing equipment manufacturing, on-site installation, commissioning, staff training, customer project operation management, spare parts supply and technical support.Customers are free to choose any one or any combination of our services.

2.What are the outstanding advantages of your company?

The one-stop service of mineral processing engineering project and equipment is our core competitiveness.

The most important feature that HZE distinguishes itself from other engineering companies, design companies or consulting companies is that we are also an equipment manufacturer with a production plant of 50,000 square meters, and we have complete manufacturing rout and the related equipment.

HZE distinguishes itself from other equipment manufacturers by owning its own R&D center and engineering design institute.

HZE distinguishes itself from many mining machinery enterprises by possessing an expert team with members including not only senior engineers of the company, but also top Chinese technical experts, university professors and researchers.

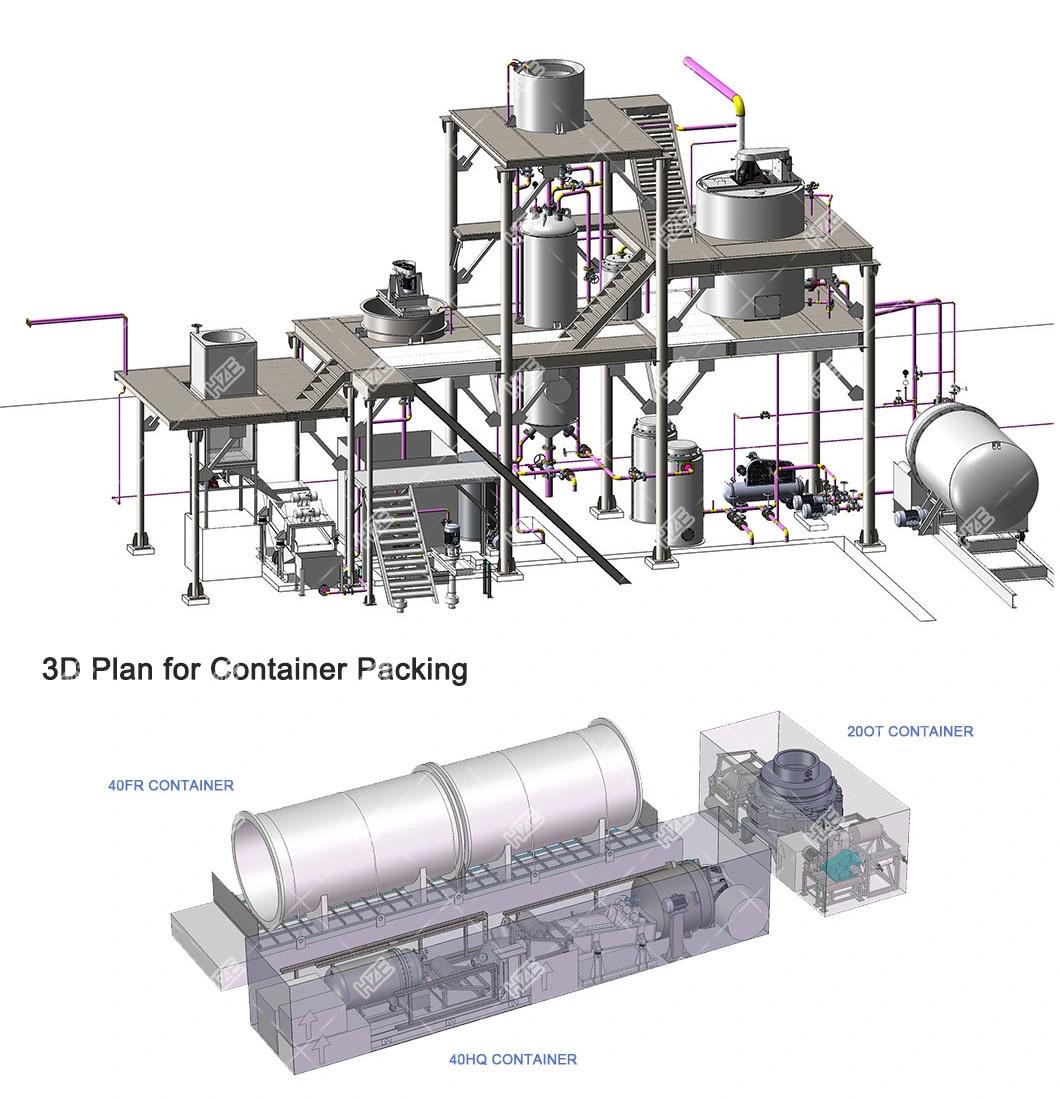

3.What are the characteristics of your company's 3D design?

HZE not only uses 3D software to design equipment, but also uses 3D software to design process flow, pipeline, steel structure, auxiliary facilities, etc.Of the whole mineral processing project.We even use 3D design for equipment packaging, container packing and equipment instructions manual.This greatly improves the quality of equipment and engineering, shortens the construction period, facilitates technical discussion and evaluation, facilitates project management, improves construction safety and reduces project cost.

4.What are the service features of your company?

- Customers who whether buy our equipment, or entrust us with EPC, or require us to provide a certain service, cooperate closely with us to carry out specific operations and supervise our implementation throughout the process.

- HZE will try to understand the basic situation and needs of customers as detailed as possible before the sale, formulate a preliminary plan according to the specific situation of customers, and get unanimous opinions after communications and discussions with customers to determine the plan.

- We set up customer files for every customer who signed the contract with us and upload them to the Cloud where customers can also get an account and password.Customers can have all the documents, videos and pictures, technology, services, execution, operation, management and control, maintenance and so on related to the business.

- Whether it is in the process of general contracting, equipment manufacturing or providing some kind of service, we welcome customers to know about our implementation on the spot or through the network, and put forward requirements and opinions.

- We assist users who have used our products to formulate operation specifications and make suggestions on maintenance plans and spare parts inventories.In addition to routine on-site installation, commissioning and training, during the production period after we handing over equipment to customers for use, we often understand the equipment using situations through the network and provide guidance and training to customer management and operators.

- For the clients who have just start the mining business, we provide the opportunity of training and practice in China's mines for the clients' employees, until they are skilled in operation and maintenance.