5% Discount Fertilizer River Sand Coal Dust Slurry Chicken Manure Sawdust Wood Chips Msw ...

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Model:Φ2.2×20

- Object:Coal Dust

- Voltage:380V

- Drum diameter:Φ1800mm

- Certification:ISO9001:2000, CE, ISO9001:2008

- Energy Saving:Energy Saving

Base Info

- Model NO.:different models

- Warranty:1 Year

- Color:Multi Color

- Customized:Customized

- Condition:New

- After-sales Service:Installation and Technical

- Application:Coal, Sawdust, Ore, Manure, Ect..

- Service:We Can Supply The Installation

- Certificate:ISO9001:2008, CE

- Transport Package:Standard Packing

- Specification:ISO9001: 2008, CE

- Trademark:HC

- Origin:Henan China

- HS Code:8419399090

- Production Capacity:50 Sets,Month

Description

Basic Info.

Model NO. different models Warranty 1 Year Color Multi Color Customized Customized Condition New After-sales Service Installation and Technical Application Coal, Sawdust, Ore, Manure, Ect.. Service We Can Supply The Installation Certificate ISO9001:2008, CE Transport Package Standard Packing Specification ISO9001: 2008, CE Trademark HC Origin Henan China HS Code 8419399090 Production Capacity 50 Sets/MonthProduct Description

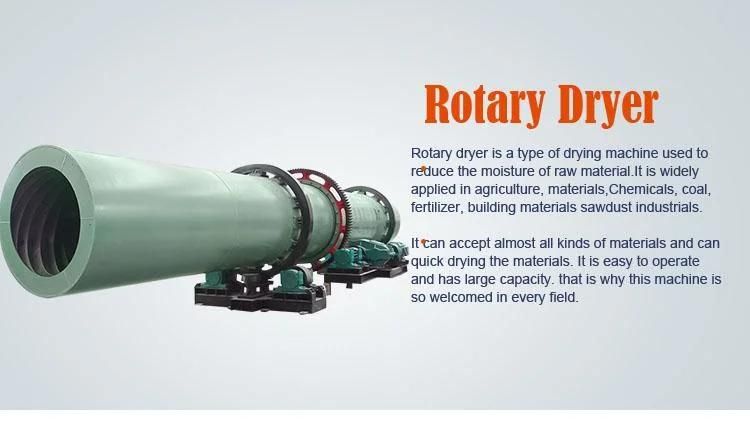

Rotary Dryer machine

New Designed Rotary Dryer Machine is a type of drying machine used to reduce the moisture of raw material, it is widely applied in agriculture, building materials, metallurgy, chemicals, coal, fertilizer, sawdust industrials.It can accept almost all kinds of materials and can quick drying the materials. It is easy to operate and has large capacity. that is why this machine is so welcomed in every field.

Technical parameter of rotary dryer:

Technical parameter of rotary dryer:| Model ( mm ) | Speed ( r/min ) | Slope ( % ) | Air Temperature ( Centigrade) | Power ( kw ) | Capacity ( t/h ) | Weight ( t ) |

| 800× 8000 | 3-8 | 3-5 | ≤ 700 | 4 | 0.8-2 | 3.5 |

| 1000× 10000 | 3-8 | 3-5 | ≤ 700 | 5.5 | 1-3 | 5.6 |

| 1200× 10000 | 3-8 | 3-5 | ≤ 700 | 7.5 | 2-3.5 | 13.5 |

| 1200× 12000 | 3-8 | 3-5 | ≤ 700 | 11 | 2.5-4 | 13.5 |

| 1500× 12000 | 2-6 | 3-5 | ≤ 800 | 11 | 4-6 | 18.5 |

| 1500× 15000 | 2-6 | 3-5 | ≤ 800 | 18.5 | 5-8 | 21 |

| 1800× 18000 | 2-6 | 3-5 | ≤ 800 | 18.5 | 6-12 | 31 |

| 2000× 18000 | 1.5-6 | 3-5 | ≤ 800 | 22 | 8-15 | 35 |

| 2200× 12000 | 1.5-6 | 3-5 | ≤ 800 | 22 | 13-15 | 31.6 |

| 2200× 14000 | 1.5-6 | 3-5 | ≤ 800 | 22 | 14-16 | 33.5 |

| 2200× 16000 | 1.5-6 | 3-5 | ≤ 800 | 30 | 14-18 | 36 |

| 2400× 18000 | 1.5-6 | 3-5 | ≤ 800 | 45 | 16-22 | 42.8 |

| 2400× 20000 | 1.5-6 | 3-5 | ≤ 800 | 45 | 18-25 | 52 |

| 3000× 20000 | 1.5-6 | 3-5 | ≤ 800 | 55 | 25-30 | 77.8 |

| 3000× 25000 | 1.5-6 | 3-5 | ≤ 800 | 55 | 28-34 | 87.5 |

Main Feature Of Good Quality Rotary Dryer

1.Wide applicability, available for many kinds of materials.

2.Simple operation, stable performance;

3.Low investment, high efficient and capacity;

4.Low cost in maintenance

Working Principle Of Good Quality Rotary Dryer

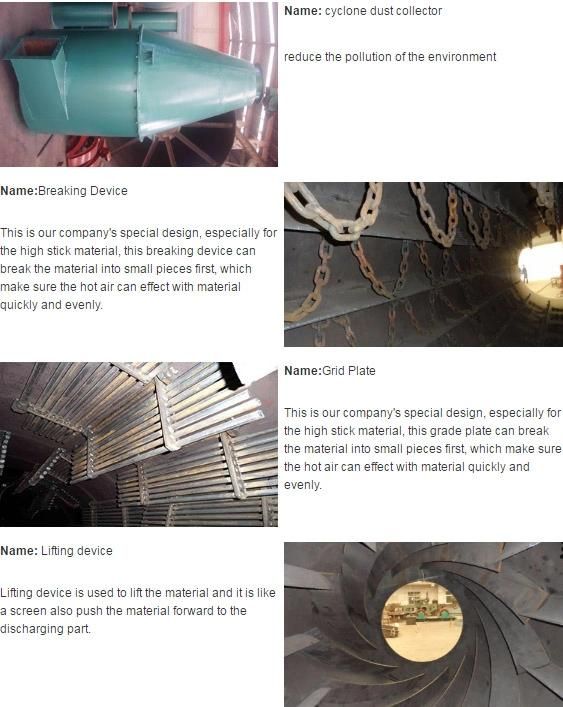

The raw material plate is arranged conveniently to allow adjustable angle positions. The material to be dried is inserted to the rotary cylinder through the raw material plate. Hot air flows within the cylinder causing the separation of water from the material by converting it into vapor which is discharged into the atmosphere. At this point, the material becomes dry.

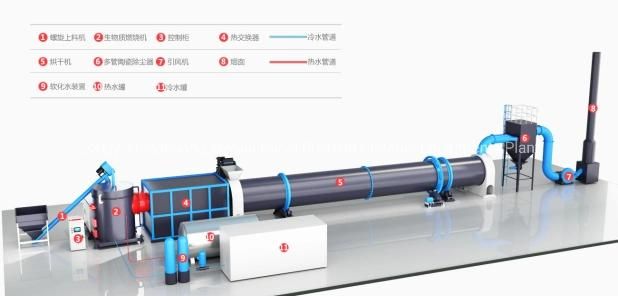

The dryer is formed by stove, rotary body, raising plate, feeder, driving device, supporting device and sealing ring, cylone and fan.

Detailed Images Good Quality Rotary Dryer

Packing & Delivery Rotary Dryer

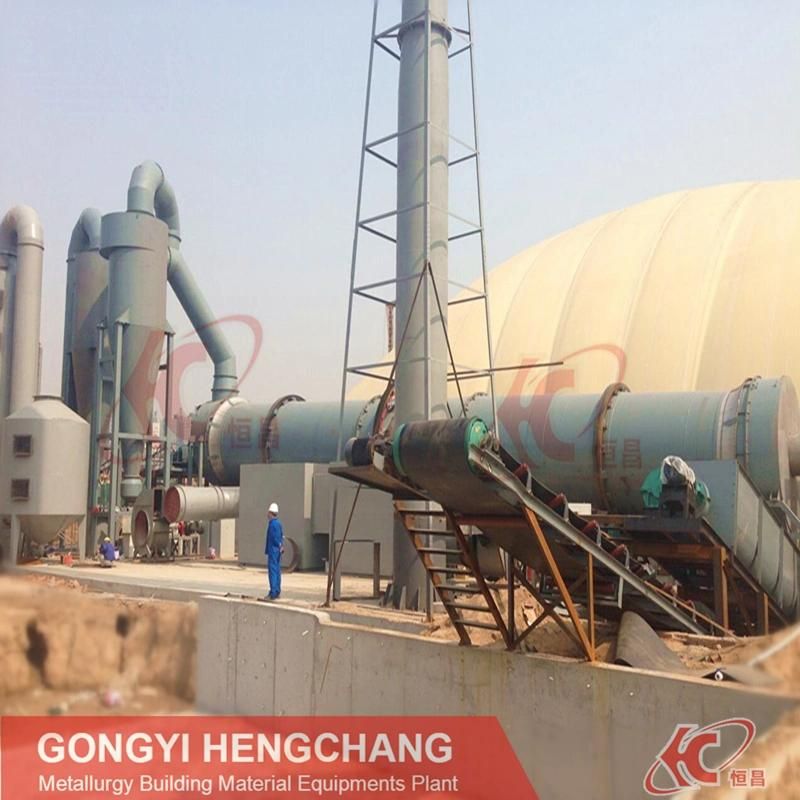

Installation Of Good Quality Rotary Dryer

Any inquiry please call us!

1. What's your raw material want to dry?

2. What's the material moisture?

3.What's the final moisture you want to get?

4.What's the capacity ton per hour you want to process?